So it begins here. I don't want to not have my car for the next few months. So I purchased the engine with turbo you will see below.

My plans, starting at the bottom and going up.

Stock pan and crank shaft - Oil shed coated pan and cryo crank shaft

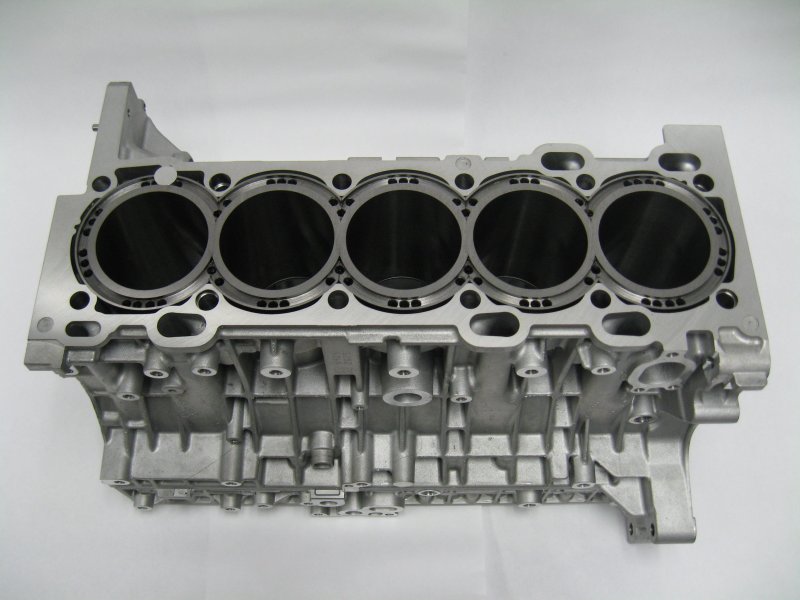

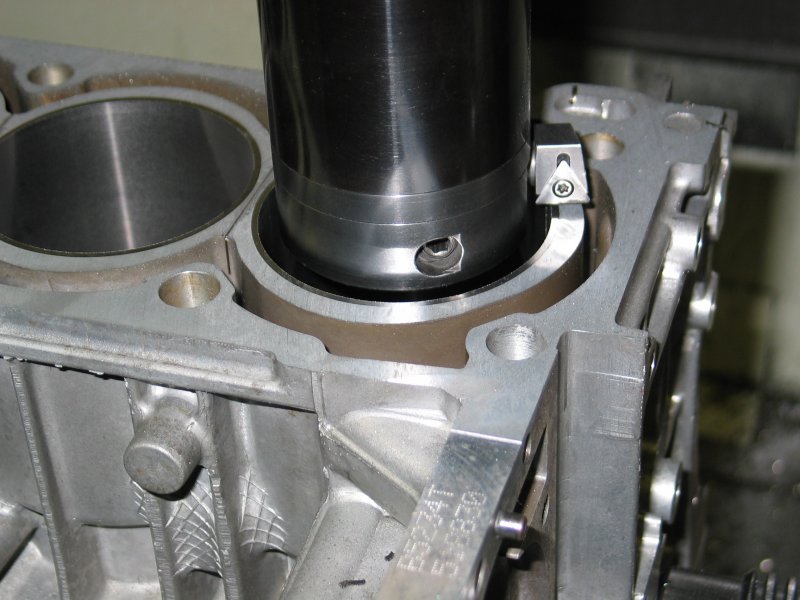

Darton Sleeves, JE pistons (9:1), Ktuned Rods (up in the air, but so far thats the idea) - All cryo'd. ceramic coated piston tops and the side coatings (forgot the name)

New exhaust valves, solid metal (undecided on exact set up), OEM intake valves - Valves cryo'd and combustion area coated. MAYBE grooving the head, KillerB sent me some really good stuff on grooved heads but I'm on the fence.

Head gasket matched and cryo'd, exhaust side ceramic coated, combustion chamber area ceramic coated. Intake "spacer" for heat reduction.

Custom (making myself) exhaust header for turbo.

Turbo... Maybe making my own hybrid, maybe rebuilding and selling the spare to buy a Garrett (undecided)

Gasket matching of the intake mani (if needed).

And I'll be open to ideas as well. Seriously, I want a killer bulletproof engine, school me. KillerB has given me a ton of information and much of this is exactly what he did but I'm doing 90% of it in my garage. The only things I cant do is Sleeve install, cryo, and i may/may not do my own ceramics.

Here is what I'm starting with. I'll be updating this every time I get some work done.

(I know its ugly, but its keeping me from having the car down.)

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

- 8-24-11

I'm officially adding an angle gear to the mix. I just ordered one and will be also stripping it to cryo treat most of the parts, put new seals in it and I will be cryo treating a new angle gear sleeve also. So hopefully I can deliver the power to the ground without worry.

Took a little time this morning and stripped 2 sides of the engine.

![Image]()

![Image]()

![Image]()

![Image]()

Exhaust side done.

![Image]()

Lost a good amount of blood but I won the battle. Had it down to the block with crank and pistons and it slid off the work surface. Tried to catch it and failed.

![Image]()

My plans, starting at the bottom and going up.

Stock pan and crank shaft - Oil shed coated pan and cryo crank shaft

Darton Sleeves, JE pistons (9:1), Ktuned Rods (up in the air, but so far thats the idea) - All cryo'd. ceramic coated piston tops and the side coatings (forgot the name)

New exhaust valves, solid metal (undecided on exact set up), OEM intake valves - Valves cryo'd and combustion area coated. MAYBE grooving the head, KillerB sent me some really good stuff on grooved heads but I'm on the fence.

Head gasket matched and cryo'd, exhaust side ceramic coated, combustion chamber area ceramic coated. Intake "spacer" for heat reduction.

Custom (making myself) exhaust header for turbo.

Turbo... Maybe making my own hybrid, maybe rebuilding and selling the spare to buy a Garrett (undecided)

Gasket matching of the intake mani (if needed).

And I'll be open to ideas as well. Seriously, I want a killer bulletproof engine, school me. KillerB has given me a ton of information and much of this is exactly what he did but I'm doing 90% of it in my garage. The only things I cant do is Sleeve install, cryo, and i may/may not do my own ceramics.

Here is what I'm starting with. I'll be updating this every time I get some work done.

(I know its ugly, but its keeping me from having the car down.)

- 8-24-11

I'm officially adding an angle gear to the mix. I just ordered one and will be also stripping it to cryo treat most of the parts, put new seals in it and I will be cryo treating a new angle gear sleeve also. So hopefully I can deliver the power to the ground without worry.

Took a little time this morning and stripped 2 sides of the engine.

Exhaust side done.

Lost a good amount of blood but I won the battle. Had it down to the block with crank and pistons and it slid off the work surface. Tried to catch it and failed.