So I decided to do a oil pressure gauge on my R since it's pretty important. First and foremost I gotta thank @wizzard_al for the tips on the project. There was actually more info on the base S60 forum than on here.

So we already have an oil pressure sensor at the front of the block, its down below the PCV box between cylinders 3 and 4. To get to it, the easiest way is to take off your intake manifold (I did my thermostat and PCV while I was there) but I realize that's more than what most of you want to do. If you take off the front bumper and the lower black plastic piece that goes below the radiator you can reach it around the subframe but it'l be tough to ensure a tight seal on everything, you need to get all these connections tighter than all hell.

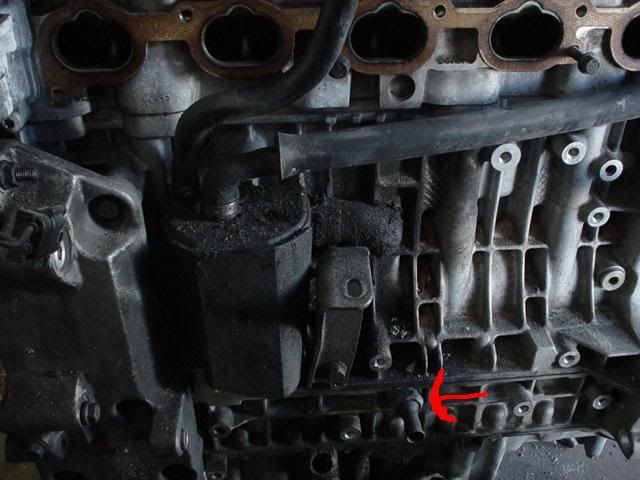

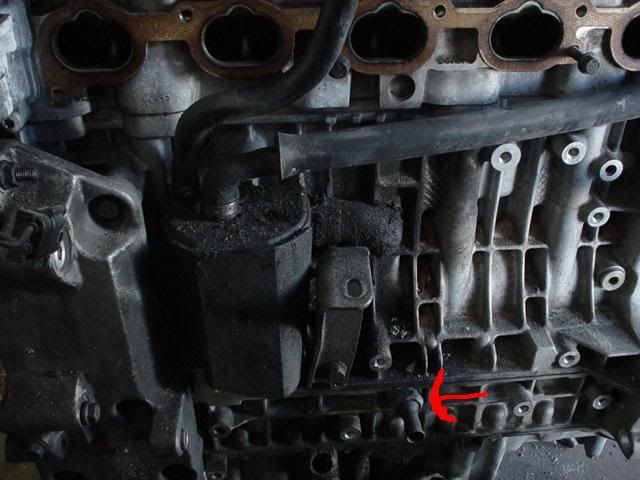

Heres a picture I found online to show where the Volvo pressure sensor is

The gauge is 14x1.5 thread and what most do is run an extender on it with a 1/8NPT tap for a gauge sensor on it however that presents an issue with adding a 5" arm moment to the threads on the block and with the vibrations, can lead to cracking of the block which isn't ideal.

My solution to this is to adapt the block to -6AN and run a braided stainless hose away from the block to put the sensors on. These AN lines are rated for thousands of PSI of pressure and won't affect the oil pressure reading at all; besides the old style of oil pressure gauges had a line running into the car to the gauge, these days there are electronic senders that stay under the hood which is what you'll want to do, I went with a ProSport Evo.

One important thing to note is that the Volvo sensor uses the threads on the sensor to ground itself to the block since there is only one wire going into the sensor itself. So to make sure it's grounded, you'll need a big ring terminal to fit around the threads of the sensor and then run that to the ground on the transmission or subframe or make another terminal to put onto the adapter on the block. I don't trust that the AN line will have sufficient ground and you really don't want the car to think its oil pressure is low...

I went with AN fittings because they are less prone to leakage and are easier to find than metric stuff.

I got everything from Summit Racing, here's the list with their part numbers:

-Block Adapter FRA-460614

-12" SS Line RUS-658490

-Gauge Adapter EAR-100199ERL

-Volvo Sensor Adapter EAR-9894DBHERL

-ARP thread sealant (optional, highly recommend) ARP-100-9904

-I got big yellow ring terminals from AdvanceAuto

-1/4" high temp conduit for the ground/power wires for both sensors

-I'd get a new Volvo oil pressure sensor, local auto stores carry them, I got one from Advance, they're common

So here's the setup I used. It goes (14x1.5 to -6AN)----(12" -6AN braided SS line)----(-6AN male to -6AN female with 1/8NPT port [hook aftermarket gauge sensor to this])----(-6AN male to 14x1.5 female)----(OEM Sensor)

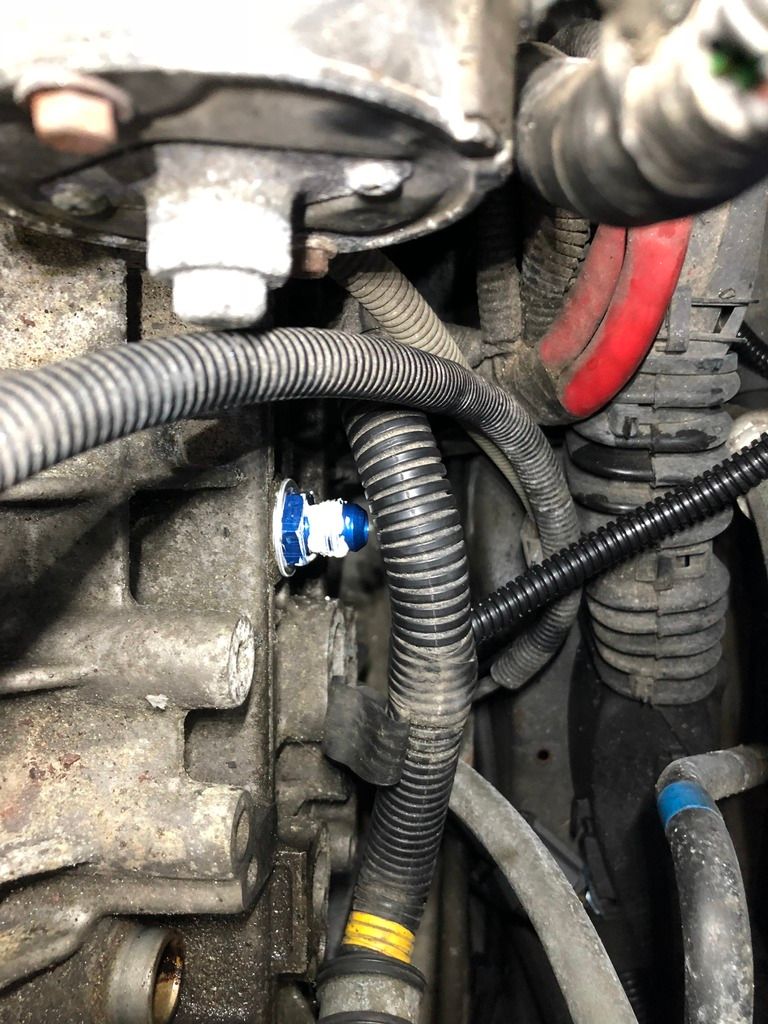

You can see the ring terminal on the Volvo sensor above, put the new seal washer under it of course.

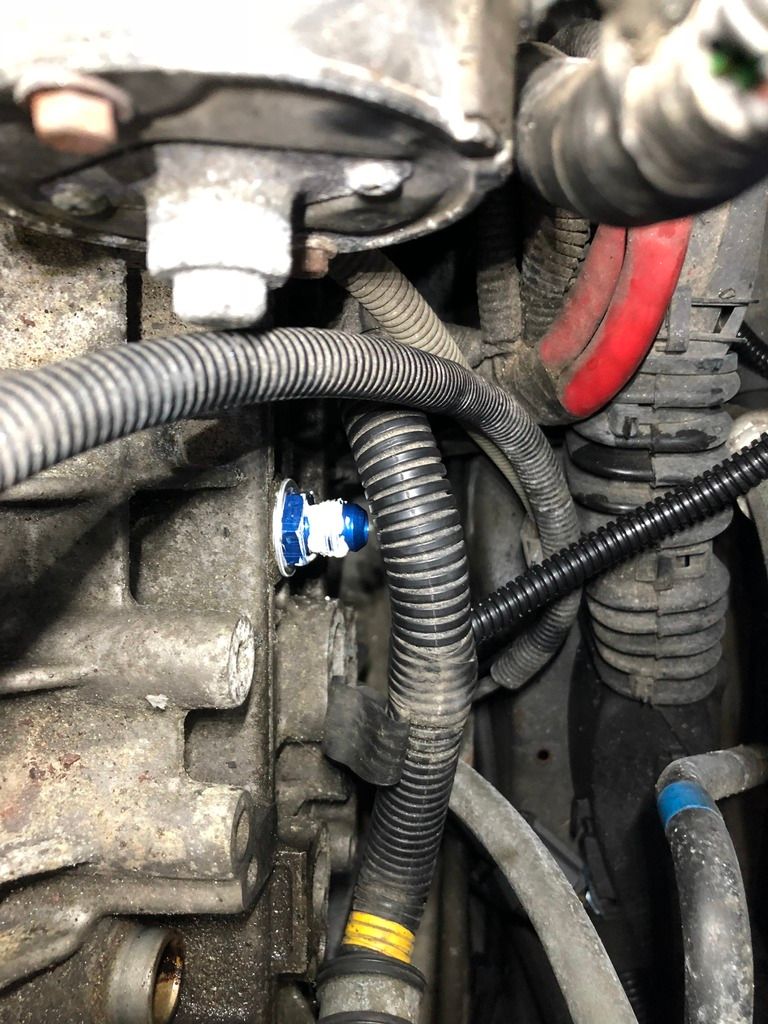

Here you can see the adapter on the block, I used some of the ARP sealant to make damn sure it won't leak. Be sure to use a new washer to the block and some sealant as well, extra will gush out not into the block since it's right hand thread.

Here's a picture of the completed line. I ran the ground to the transmission and I then zip tied the end of the line to the AC lines. You can make something better, maybe a 90* aluminum piece bolted to the subframe to cradle the end of the line.

Another thing to note which you can see in the above picture is that you will need to extend the wire for the Volvo sensor by around 16". So obviously cut the connector off and solder on a wire and solder the connector to the end of that wire, get you some 1/4" conduit from Summit Racing to cover the new line.

That's about it! Run the sensor wiring to your gauge inside the car and you can get accurate oil pressure readings. This isn't the easiest way to do it but it's the safest way.

So we already have an oil pressure sensor at the front of the block, its down below the PCV box between cylinders 3 and 4. To get to it, the easiest way is to take off your intake manifold (I did my thermostat and PCV while I was there) but I realize that's more than what most of you want to do. If you take off the front bumper and the lower black plastic piece that goes below the radiator you can reach it around the subframe but it'l be tough to ensure a tight seal on everything, you need to get all these connections tighter than all hell.

Heres a picture I found online to show where the Volvo pressure sensor is

The gauge is 14x1.5 thread and what most do is run an extender on it with a 1/8NPT tap for a gauge sensor on it however that presents an issue with adding a 5" arm moment to the threads on the block and with the vibrations, can lead to cracking of the block which isn't ideal.

My solution to this is to adapt the block to -6AN and run a braided stainless hose away from the block to put the sensors on. These AN lines are rated for thousands of PSI of pressure and won't affect the oil pressure reading at all; besides the old style of oil pressure gauges had a line running into the car to the gauge, these days there are electronic senders that stay under the hood which is what you'll want to do, I went with a ProSport Evo.

One important thing to note is that the Volvo sensor uses the threads on the sensor to ground itself to the block since there is only one wire going into the sensor itself. So to make sure it's grounded, you'll need a big ring terminal to fit around the threads of the sensor and then run that to the ground on the transmission or subframe or make another terminal to put onto the adapter on the block. I don't trust that the AN line will have sufficient ground and you really don't want the car to think its oil pressure is low...

I went with AN fittings because they are less prone to leakage and are easier to find than metric stuff.

I got everything from Summit Racing, here's the list with their part numbers:

-Block Adapter FRA-460614

-12" SS Line RUS-658490

-Gauge Adapter EAR-100199ERL

-Volvo Sensor Adapter EAR-9894DBHERL

-ARP thread sealant (optional, highly recommend) ARP-100-9904

-I got big yellow ring terminals from AdvanceAuto

-1/4" high temp conduit for the ground/power wires for both sensors

-I'd get a new Volvo oil pressure sensor, local auto stores carry them, I got one from Advance, they're common

So here's the setup I used. It goes (14x1.5 to -6AN)----(12" -6AN braided SS line)----(-6AN male to -6AN female with 1/8NPT port [hook aftermarket gauge sensor to this])----(-6AN male to 14x1.5 female)----(OEM Sensor)

You can see the ring terminal on the Volvo sensor above, put the new seal washer under it of course.

Here you can see the adapter on the block, I used some of the ARP sealant to make damn sure it won't leak. Be sure to use a new washer to the block and some sealant as well, extra will gush out not into the block since it's right hand thread.

Here's a picture of the completed line. I ran the ground to the transmission and I then zip tied the end of the line to the AC lines. You can make something better, maybe a 90* aluminum piece bolted to the subframe to cradle the end of the line.

Another thing to note which you can see in the above picture is that you will need to extend the wire for the Volvo sensor by around 16". So obviously cut the connector off and solder on a wire and solder the connector to the end of that wire, get you some 1/4" conduit from Summit Racing to cover the new line.

That's about it! Run the sensor wiring to your gauge inside the car and you can get accurate oil pressure readings. This isn't the easiest way to do it but it's the safest way.