So, my fuel pump was on its way out and causing codes, and I didn't feel like paying for a full assembly since just the pump is not available. The cheapest one on rockauto is over $200, close to the cost of an OEM pump module from tasca.

I noticed on the Viva site that there is an Aeromotive upgrade pump (340 lph) that fits the stock assembly for cosiderably less money than the stock replacement options.

http://www.vivaperformance.com/aeromotive-fuel-pump-upgrade-volvo-s60r-v70r/

The site says that there is some "shaving" of the stock module to make it fit, but I could find no info on previous attempts to fit this pump. It is an Aeromotive P/N 11142.

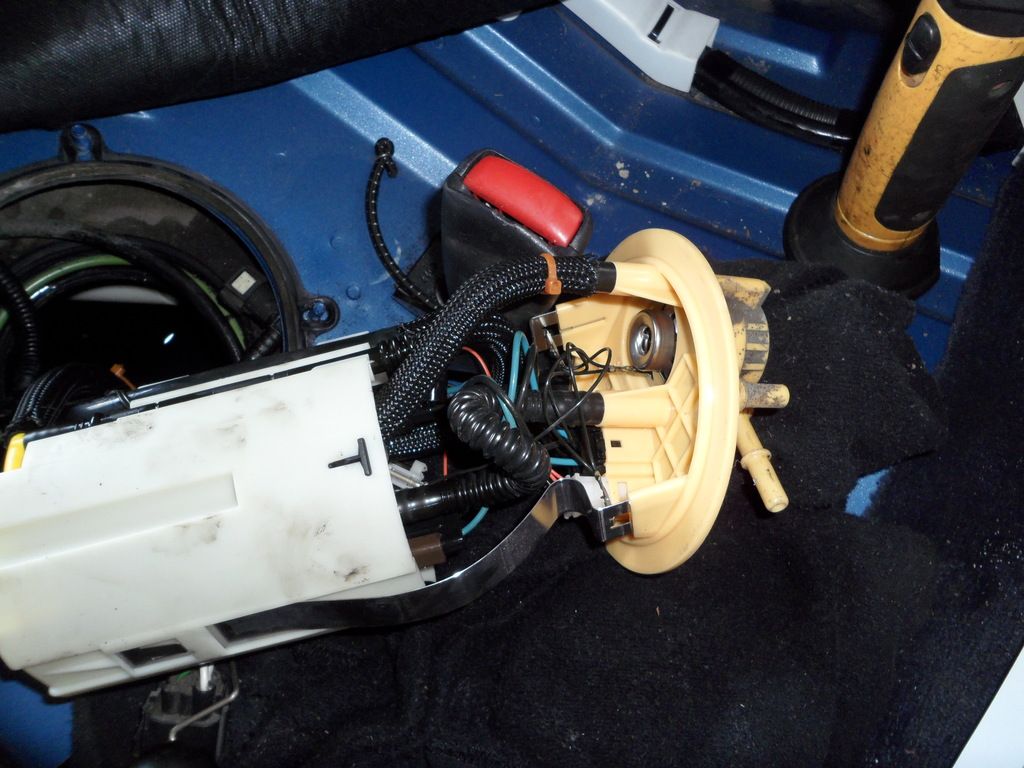

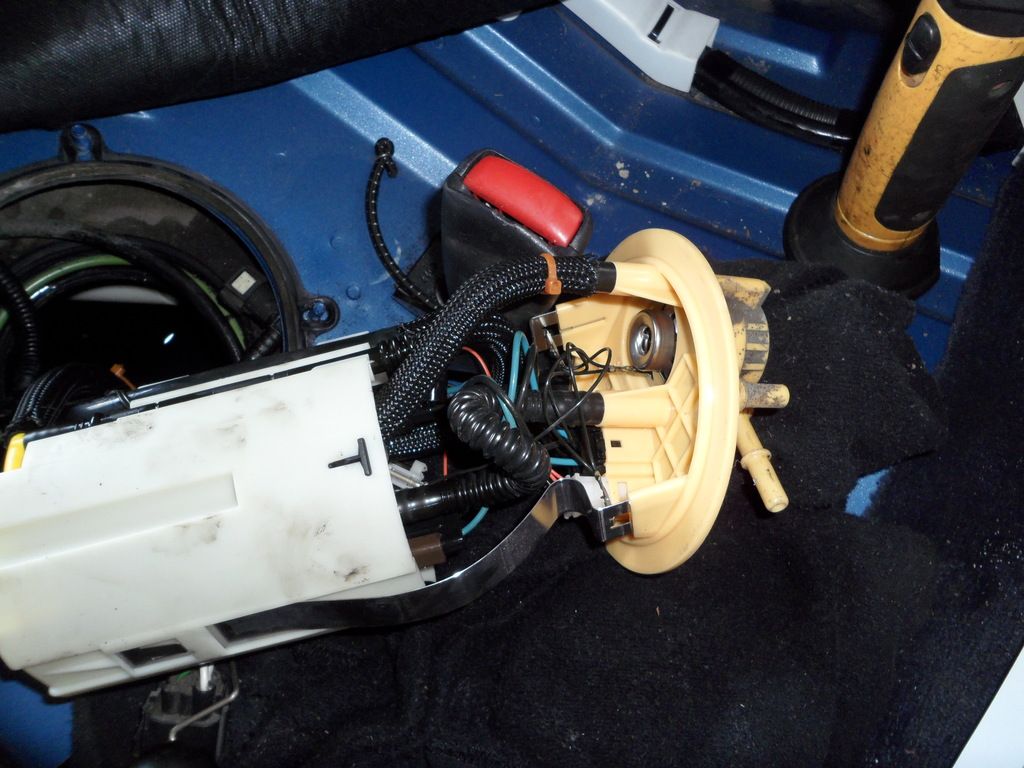

So, I removed the pump assembly in the same way I would if I were replacing the assemby, and here is what it looks like:

There are 2 pumps in the assembly, one transfers fuel from the other side, the other actually supplies it to the engine...this is the unit that needs replacement. It is the pump with a hose going to the top of the module.

To replace the pump, you need to disassemble the module. I didn't take any more photos, because I was covered with gasoline, but it goes like this:

1. Unhook the level sensor from the white cup, you can leave it plugged in electrically.

2. Undo the 3 black clips the hold the pump holder into the cup; they just snap inward.

3. Release the steel spring retaining clips that connect the top of the module to the white cup.

4. Release the hose going from the transfer pump (clipped into the side of the white cup) while pulling the pump holder out of the white cup.

5. Disconnect the stock pump wiring and remove the hose from the top of the assembly (I had to slit mine open). Remove the pump from the black holder and discard.

At this point, you need to enlarge the space in the holder, as the Aeromotive pump is a little bigger in diameter. I used a curved metal file, it was a pain in the butt. You are filing around sensitive parts AND creating lots of dust, and you need to remove more material than you think. Keep test fitting the pump. I eventually used a little motor oil to let the pump slide in, I still had to force it.

While everything was still apart, I sprayed it all down with brake cleaner to remove the plastic dust, etc. Be sure to get the screen on the bottom of the pump pickups, mine had some dust after 133k.

Attach the hose included with the pump to the top of the module and reassemble everything. I had to iterate a few times to get the right length on the rubber hose, it was about 1/3" longer than needed. I just realized that this hose is shortened when you push the module down into the tank and tighten the lock ring. The stock hose had a loop in it, the Aeromotive hose was straight. I hope my hose didn't kink when I installed the module...the car ran fine afterward and had a normal pump duty cycle with no codes, but I will keep an eye on it. I recommend picking up a longer piece of fuel injection hose and creating a loop like the stock hose, then compressing the module down to make sure it doesn't develop a kink.

The stock harness attaches normally, but there is no place for the little separate ground wire to go. I wrapped mine around the other wiring to keep it out of the way...I don't know if this is a problem, I have never seen a pump with a ground connection.

Other than that, it is normal reassembly. The pump is a bit quieter than stock IMO, and it does not affect the way the car runs and drives.

I noticed on the Viva site that there is an Aeromotive upgrade pump (340 lph) that fits the stock assembly for cosiderably less money than the stock replacement options.

http://www.vivaperformance.com/aeromotive-fuel-pump-upgrade-volvo-s60r-v70r/

The site says that there is some "shaving" of the stock module to make it fit, but I could find no info on previous attempts to fit this pump. It is an Aeromotive P/N 11142.

So, I removed the pump assembly in the same way I would if I were replacing the assemby, and here is what it looks like:

There are 2 pumps in the assembly, one transfers fuel from the other side, the other actually supplies it to the engine...this is the unit that needs replacement. It is the pump with a hose going to the top of the module.

To replace the pump, you need to disassemble the module. I didn't take any more photos, because I was covered with gasoline, but it goes like this:

1. Unhook the level sensor from the white cup, you can leave it plugged in electrically.

2. Undo the 3 black clips the hold the pump holder into the cup; they just snap inward.

3. Release the steel spring retaining clips that connect the top of the module to the white cup.

4. Release the hose going from the transfer pump (clipped into the side of the white cup) while pulling the pump holder out of the white cup.

5. Disconnect the stock pump wiring and remove the hose from the top of the assembly (I had to slit mine open). Remove the pump from the black holder and discard.

At this point, you need to enlarge the space in the holder, as the Aeromotive pump is a little bigger in diameter. I used a curved metal file, it was a pain in the butt. You are filing around sensitive parts AND creating lots of dust, and you need to remove more material than you think. Keep test fitting the pump. I eventually used a little motor oil to let the pump slide in, I still had to force it.

While everything was still apart, I sprayed it all down with brake cleaner to remove the plastic dust, etc. Be sure to get the screen on the bottom of the pump pickups, mine had some dust after 133k.

Attach the hose included with the pump to the top of the module and reassemble everything. I had to iterate a few times to get the right length on the rubber hose, it was about 1/3" longer than needed. I just realized that this hose is shortened when you push the module down into the tank and tighten the lock ring. The stock hose had a loop in it, the Aeromotive hose was straight. I hope my hose didn't kink when I installed the module...the car ran fine afterward and had a normal pump duty cycle with no codes, but I will keep an eye on it. I recommend picking up a longer piece of fuel injection hose and creating a loop like the stock hose, then compressing the module down to make sure it doesn't develop a kink.

The stock harness attaches normally, but there is no place for the little separate ground wire to go. I wrapped mine around the other wiring to keep it out of the way...I don't know if this is a problem, I have never seen a pump with a ground connection.

Other than that, it is normal reassembly. The pump is a bit quieter than stock IMO, and it does not affect the way the car runs and drives.